GRANTERRE

AUTOMATION IN ACTION:

THE GRANTERRE SUCCESS STORY.

CUSTOMER INTRODUCTION

GranTerre: italian excellence between tradition and innovation

GranTerre is one of the leading groups in the Italian agrifood industry. It was established in 2019 through the merger of two historic companies in the sector, Grandi Salumifici Italiani and Parmareggio, and is headquartered in Modena, in the heart of Emilia. Today, it is a benchmark in the production and marketing of cured meats and aged cheeses, thanks to well-known brands such as Casa Modena, Parmareggio, Senfter and Agriform.

The company enhances products that symbolize Italian tradition, such as Parma Ham, Speck, mortadella, Parmigiano Reggiano and Grana Padano, maintaining direct control over the supply chain to ensure quality and consistent production. With multiple plants across Italy and a solid presence abroad, GranTerre combines strong local roots, industrial expertise and a commitment to sustainability, preserving the authentic bond between each product and its territory of origin.

.

THE CHALLENGE

MANAGING COMPLEXITY, ENABLING EXCELLENCE

In the evolution of its production and logistics processes, GranTerre faced a series of complex challenges. Managing heterogeneous resources distributed across limited physical spaces required precise coordination without risking bottlenecks or operational interruptions. As internal flows and the variety of handling activities increased, ensuring the safety of people and products became a critical factor, especially in an environment where automation and manual activities coexist. At the same time, it was essential to maintain high performance despite growing operational complexity, finding the right balance between efficiency and flexibility to respond to dynamic and sometimes unpredictable production needs. Another challenge was integrating the human factor into automated processes without reducing control, responsiveness or operator accountability. Finally, GranTerre needed complete and centralized visibility over all flows, with connected and reliable systems capable of providing end to end control of the entire logistics process

.

- Coordinate different resources in limited spaces without operational downtime

- Keep high safety standards with complex logistics flows

- Ensure high performance even with increasing volumes and variability

- Balance efficiency and flexibility in dynamic production environments

- Integrate operators and automation while maintaining control and responsiveness

- Ensure and to end visibility and control through connected and reliable systems

THE SOLUTION

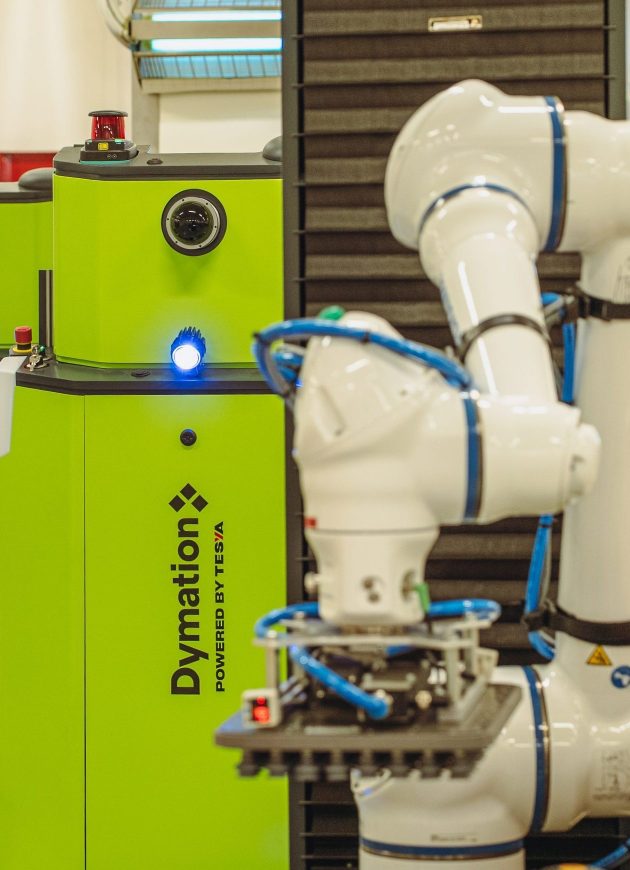

DYMATION MEETS COMPLEXITY WITH A SCALABLE ECOSYSTEM

A solution that harmonizes people, automation and technology into a single oeprational flow

HUMAN CENTRIC AUTOMATION

INTEGRATED AND PROACTIVE SAFETY

Automation must ensure operator safety at every moment of their workday

COLLABORATION, NOT REPLACEMENT

Machines enhance and elevate human work by eliminating repetitive tasks

FLEXIBILITY AND ARTIFICIAL INTELLIGENCE

Automation adapts to production rhythms and suggests priorities adna ctions to the operator

DYMATION BENEFITS

INCREASED SAFETY

Automatic vehicles and safer routes ensure human-machine coexistence even in limited spaces

INCREASED PRODUCTIVITY

Faster, interruption-free flows thanks to the integration of palletizers, AMRs and management software

ORDER AND CLEANLINESS

Clear and organized spaces male warehouse contrl easier and reduce the risk of accidents

PEOPLE EMPOWERMENT

Operators focus on value-added activities. By reducing physical strain and repetitive actions, work quality and perceived well-being improve

OPERATIONAL FLEXIBILITY

The system suggests whether an activity should be handled by an operator or by a machine, adapting in real time to the ecosystem

SCALABLE SYSTEM

A solution ready to grow with the company: new robots, new modules, same architecture

Dymation turns potential into competitiveness.

Change becomes efficiency.

Tomorrow becomes today.

This is innovation, with Dymation.